User story with Brasserie Castelain

On this page, you will find a user story about Brasserie Castelain. This featured story informs about the use of our Intermediate Bulk Container (IBC), the VARIBOX Full Containment (FC) in their activities, and the reasons for Castelain’s choice for the VARIBOX. Our sales manager in France, Mr. Sébastien Dufour, spoke to Ms. Maud Carrière, QHSE manager.

Could you please tell us about more Brasserie Castelain?

Since its inception, Brasserie Castelain has been independent, family-run, and deeply rooted in its territory. Today, the small Bénifontaine brewery has grown to a team of 48 employees who work alongside the Castelain family daily to create tasting beers combining tradition and innovation. The main objective of the Castelain Brewery is to be artisans and creators of taste, passionate about their craft as brewers, and to offer quality products, based on real know-how, to beer lovers.

What are the products in the current IBCs used for and how are they stored?

The IBCs are mainly used to contain cleaning products. What you should know is, that the world of brewing is a bit like the world of dairy. It is fair to say that 50% of operators’ time is dedicated to cleaning the tanks. Even if our facilities do not present any major microbial or pathogenic risks for humans, these risks can still lead to quality problems or organoleptic defects. That’s why we have to spend a lot of time cleaning the tanks.

The current storage solution is therefore filled with chlorine and acid solutions which will be used for cleaning all the vats in the brewing room, in the fermentation part, the guard part as well as the racking part.

What are the reasons that led you to find solutions to improve your installation?

The main reason was the safety of the people operating in our facilities. The chemical room was starting to show signs of weakness in terms of retention and no longer reached the optimum level of safety desired by our brewery. Before these weaknesses lead to any mishap, we decided to take matters into our own hands. Having already observed the effectiveness of this type of VARIBOX container with fellow brewers, we contacted you to find a solution adapted to our company that guarantees the safety of our employees.

Is the safety aspect of VARIBOX the main factor favoring the use of VARIBOX?

Yes, the safety that VARIBOX can offer is an argument in favor of their use. The simplicity of use of this type of container is also a positive point for us. We were looking to simplify chemical transfer steps while making them safer, and VARIBOX perfectly met this need. The Safeline extractor and connection solution contributes to a high level of security during transfer. We also sought to simplify the task of the operator who thanks to VARIBOX gains in simplicity, fluidity, and therefore efficiency.

Has the use of VARIBOX contributed to your environmental goals?

Human safety is very important to us, even as is the environmental impact. With VARIBOX, we are certain of limiting the chemical risk and the potential accidents that this risk can cause while respecting our desire to limit the environmental impact of the company. So today we are completely satisfied with VARIBOX, which allows us to ensure both the safety of our people and the safety of the environment.

Regarding the VARIBOX models directly, you have opted for the VARIBOX 1000 FC as well as for the VARIBOX 250 CC. Why these choices?

It is quite simply the flexibility of the volumes that guided our choices. The VARIBOX 1000 liters are used for solutions with very regular or even daily use in certain cases. On the other hand, the VARIBOX 250 CC serves as a container for solutions with more weekly or monthly uses. The choice of different models allowed us to re-order the 1000 liters once every fortnight and the 250 liters rather than once a month.

To sum up, the VARIBOXs provided us with the solution perfectly suited to our needs and more generally suited to the identity of our company, considering our desire to reduce waste.

In addition, we are very satisfied with the technical advantages of VARIBOX which with its durability and design has completely seduced us.

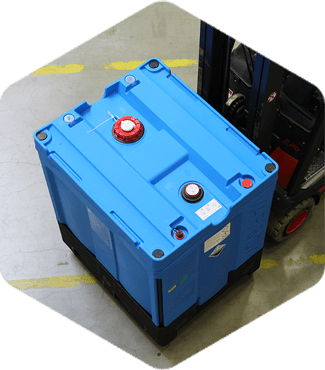

The installation with the VARIBOX:

User story with Brasserie Castelain & VARIBOX FC 1000

The double-walled VARIBOX is available in an EPDM or Viton version depending on the chemicals that will be packed in the container. This will be fully matched to the Safeline system. But of course, the VARIBOX FC is also applicable for other extractor tubes. The full containment IBCs are available in many different colors as blue, dark blue, yellow, orange, green, and natural to match your product coding. Next to that, to be 100% safe the containers are equipped with automatic venting in terms of a pressure relief vent or combi-vent.