User story with Refresco

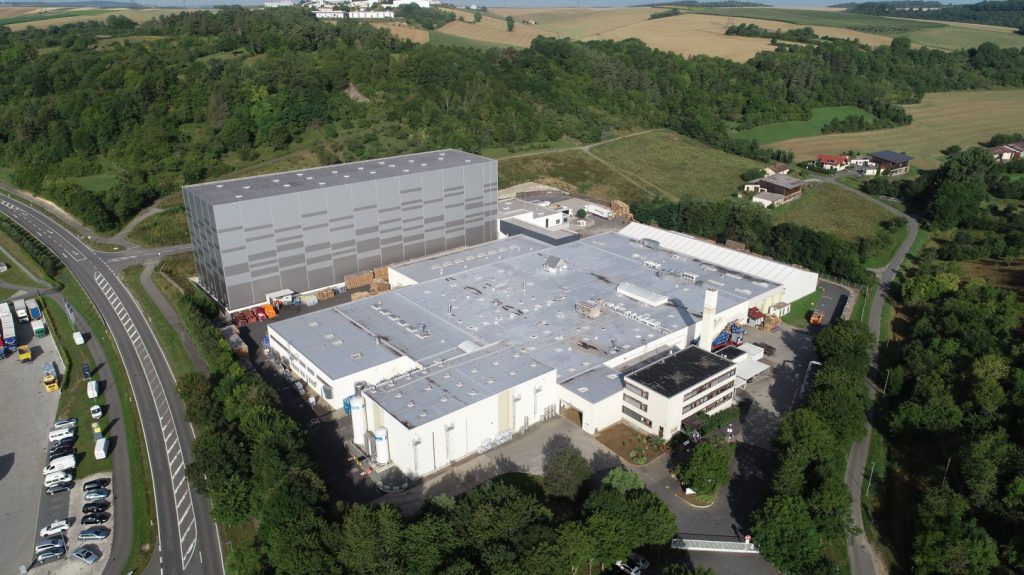

On this page, you will see our user story with Refresco. In this application, you can see how Refresco optimally uses the VARIBOX FC. Our New Business Manager Kobus Bruins interviewed Andreas Schenk, Operations Manager at Refresco in Grünsfeld. Refresco Deutschland GmbH with its head office in Mönchengladbach and four production sites nationwide is one of the leading beverage manufacturers in Germany and part of the international Refresco Group.

Interview with Andreas Schenk

Until recently, the cleaning agents were delivered to the Grünsfeld plant in 220 liters plastic drums. Why were you not satisfied with this situation?

In our opinion, transport in the factory with drums standing on pallets is not safe enough. Handling these barrels is very complex for the employees. It is not easy to place the drums on a separate drip pan. We wanted to increase the occupational safety of the employees and came across the double-walled IBC VARIBOX.

What are the advantages of the VARIBOX over the drums?

With the VARIBOX FC, no additional drip tray is necessary because it has an integrated drip tray. This not only saves space, but all rooms where cleaning agents are used also remain clean.

In addition, with the VARIBOX we can implement a quick and safe change. We no longer have to remove a lance as with the drums. In this way, the employees no longer come into contact with the hazardous substances.

User story with Refresco

How do you make a contribution to sustainability?

The VARIBOX is a reliable reusable packaging that can be used for several years. The VARIBOX is filled again and again and not disposed of, as was the case with the drums. The bottom of the VARIBOX can be compared to the shape of a bathtub with its drain. Using an integrated suction lance, we can practically completely empty the VARIBOX. It no longer has to be manually emptied for transport, which means a great plus in terms of safety for us.

How does the VARIBOX fit with the regulations regarding chemicals and the handling of water-polluting liquids?

In addition to being approved as UN transport packaging, VARIBOX also has general approval for its integrated spill containment from the German Institute for Building Technology (DIBt). According to the AwSV, plants must retain any water-polluting substances in a suitable manner. The integrated spill containment of the VARIBOX is impermeable to liquids and has no drains.

What is Refresco planning to do at the other locations in Germany? Do you want to change there too?

In any case, I will introduce this new system to my colleagues in the other plants. Technically clean and safe solutions are gladly implemented everywhere

The situation before

- Transport in the factory with containers on pallets is not safe enough

- Placing the barrels and IBCs on a drip tray is very complex for the employees

- To empty the barrels and IBCs, separate pumps are used, which leak when they are removed

- The drums and IBCs are open, toxic fumes can be released

- The packaging is not completely empty, residue has to be removed before the packaging is shipped

The new situation

- With the VARIBOX no extra drip tray is needed because it has an integrated spill containment

- The rooms where the VARIBOX are used remain clean

- The extractor tube does not have to be removed as with the drums and standard IBCs

- The employees can not get in contact with no chemical products

- With the VARIBOX, the work safety of employees can be improved quickly

More information about user story with Refresco

Do you have any specific questions regarding this featured story with Refresco or to the VARIBOX FC, or do you want additional information please feel free to contact us at info@varibox-ibc.com or you can call +31 (0) 570 660 711