Drumtainers at the CSA

VARIBOX Drumtainers at the CSA, the central sterilization department of the hospital “Medisch Spectrum Twente”, sterilize all medical instruments in the hospital in Enschede. This is done very carefully so that doctors and nurses can do their work in time with the right instruments. The CSA plays an important role in ensuring optimum patient safety.

Mr Domhof, how does this process work?

“The medical instruments from the outpatient clinics and operating theatres come to the CSA to be cleaned, disinfected, and sterilized. The transport carts and transport containers are also cleaned and disinfected here.”

“For this, the CSA has machine cleaning processes. The cleaning agents used for this are contained in 200-liter drums supplied by Dr. Weigert.”

Mr. Baan, how are the cleaning agents dosed?

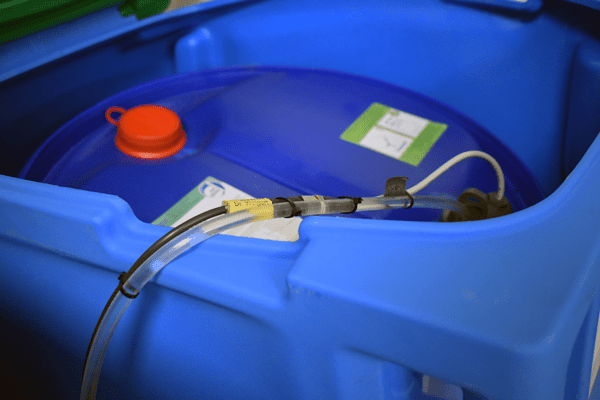

“The cleaning and disinfection products are dosed fully automatically in the cleaning machines. To do this, the Drumtainer is placed and connected to a dosage station developed by Dr. Weigert. This dosing station controls automatically with a unique RFID chip in the Drumtainer whether the right product is connected and the best-before-date has not expired. Only then is dispensing released and product pumped to the cleaning machines.”

How is safety for users ensured?

“It goes without saying that personal protective equipment such as gloves, apron, and safety glasses are used when connecting the drums. The RFID chip rules out the possibility of mixing up cleaning products, thus preventing a possible calamity. From delivery to return, the 200-liter drum remains safely in the Drumtainer. All the time, the Drumtainer acts as a spill container: in case of leakage, the chemical product is safely collected.”

Drumtainers at the CSA

Mr. Domhof, how did that work in the old situation?

“Before, the cleaning products came in 20-liter cans. That meant a lot of dragging with the heavy cans, which weighed about 25 kg each. They also had to be placed on a spill container, by hand. The limited capacity of a can also mean that they had to be changed frequently, resulting in a lot of waste and risk of spillage every time.”

What do you think of the Drumtainer?

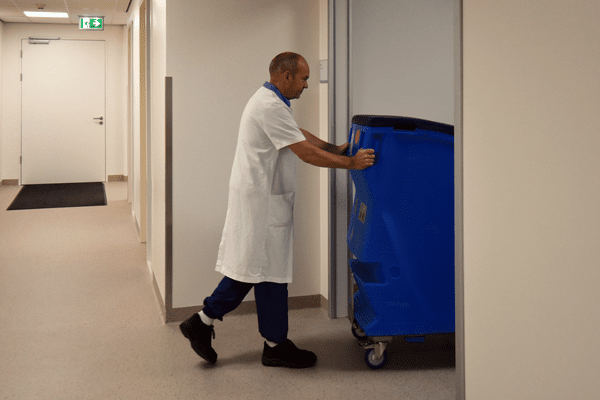

“The arrival of the Drumtainer meant the end of dragging cans around. The Drumtainer is significantly less stressful for me and my colleagues.”

“The handles are in exactly the right places: you can maneuver it well, also through narrow corridors, in lifts, and through doors. Because there are 10 times as many in it, it also lasts 10 times longer and you don’t have to change an empty one as often. The barrel is slightly tilted and therefore you have very little residual product. The key and instructions for use are in the lid: handy because if you fold it up you have everything to hand for connecting. And when you close the lid, the connection is safely protected.”