Cleaning in place with the VARIBOX at Refresco

Cleaning in place with VARIBOX. After a great first story at Refresco in Grünsfeld, we have a fantastic new story about the VARIBOX at this company. Our New Business manager Kobus Bruins now visited the Refresco location in Herrath, where Kobus spoke with Mr. Hammel. Mr. Hammel has an engineering background and moved later in his career to health and safety. Today, Mr. Hammel is responsible for Health and Safety at the Refresco locations of Herrath and Erftstadt. This unique 180-degree turn enables him to fully understand the many different employee working situations. All in all, a perfect day to discuss safety topics.

Mr. Hammel, you have multiple dosing stations for detergents here at the location of Herrath. Where do you use the VARIBOX for?

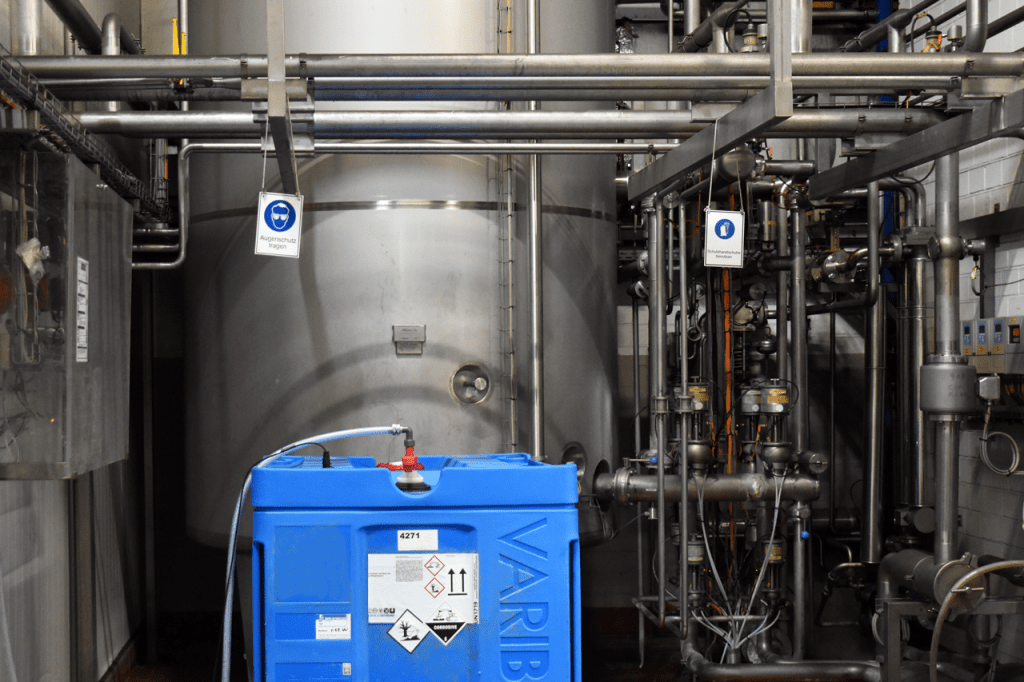

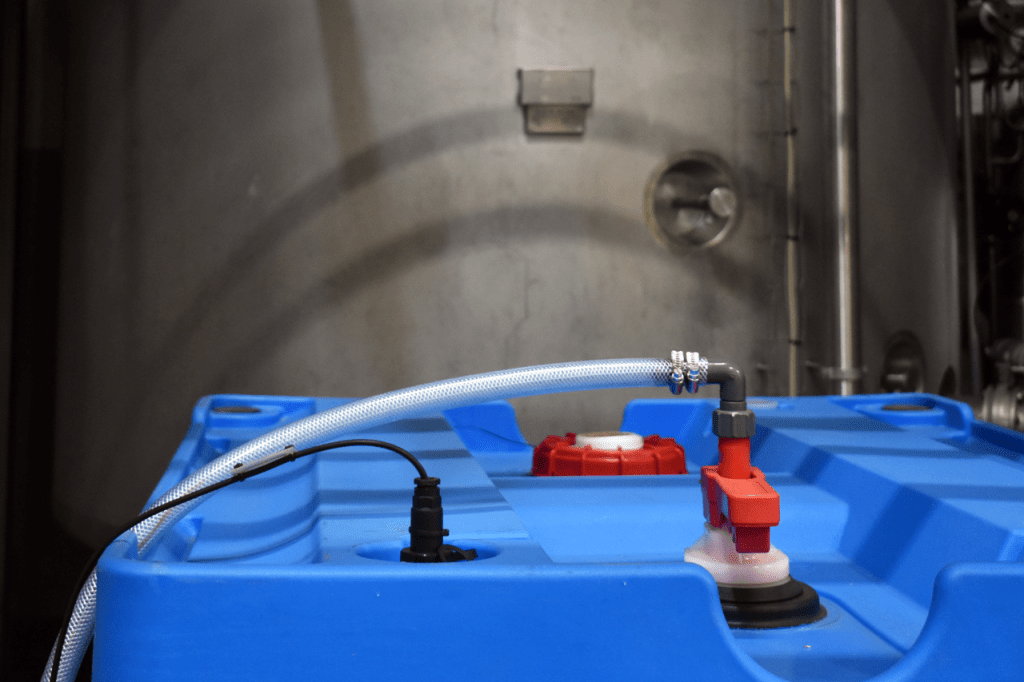

Here in Herrath we are using the VARIBOX for CIP, Cleaning in Place. CIP is used to clean all pipes and storage tanks. These must be cleaned very thoroughly to meet hygiene and quality requirements. As you may know, we are producing lots of acidic juices. Therefore, the detergents we use for this purpose have lye-based properties. The lye-based detergents are used for cleaning germ-free pipes, storage tanks, and filling lines (CIP). Today we use the VARIBOX for CIP at the German locations of Grünsfeld, Herrath and Erftstadt. The location in Calvörde has still to be transferred.

We want to make another improvement in safety using the smaller VARIBOX. Our supplier of detergents has meanwhile agreed to also replace the supply of 200-liter drums with the VARIBOX CC 250 liters IBC. We want to use this VARIBOX CC for acid-based cleaners: in terms of quantities, it is more appropriate to use the smaller container.

Cleaning in place with VARIBOX

“Mr. Hammel; VARIBOX is faster, simpler and most important safer”

Mr. Hammel, Refresco has decided to use the VARIBOX Full Containment in Herrath, what were the reasons for this decision?

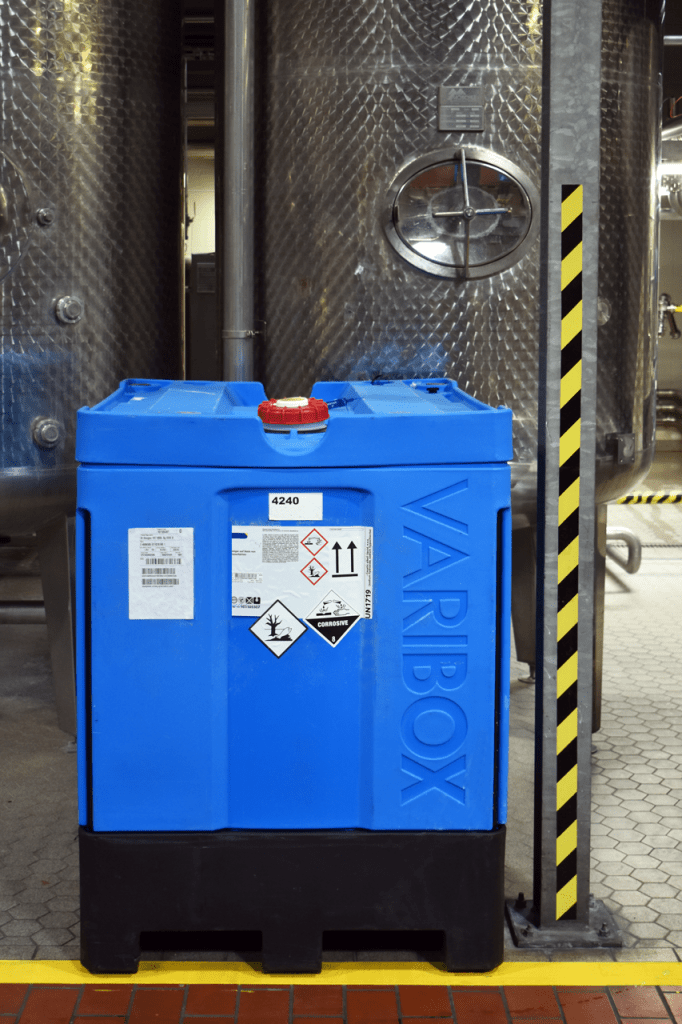

The main reason for this decision was safety. We wanted to increase the safe handling of the detergents that we use in our factory. The VARIBOX saves a lot of space in our factory with the integrated drip tray. Next to that, there is no need to open the lid to put a suction tube in the opening to empty the IBC.

Very important is that we don’t need to use a forklift truck to lift the IBC onto a drip tray. We are now only using a much safer electric pallet jack. This is a huge improvement in safety.

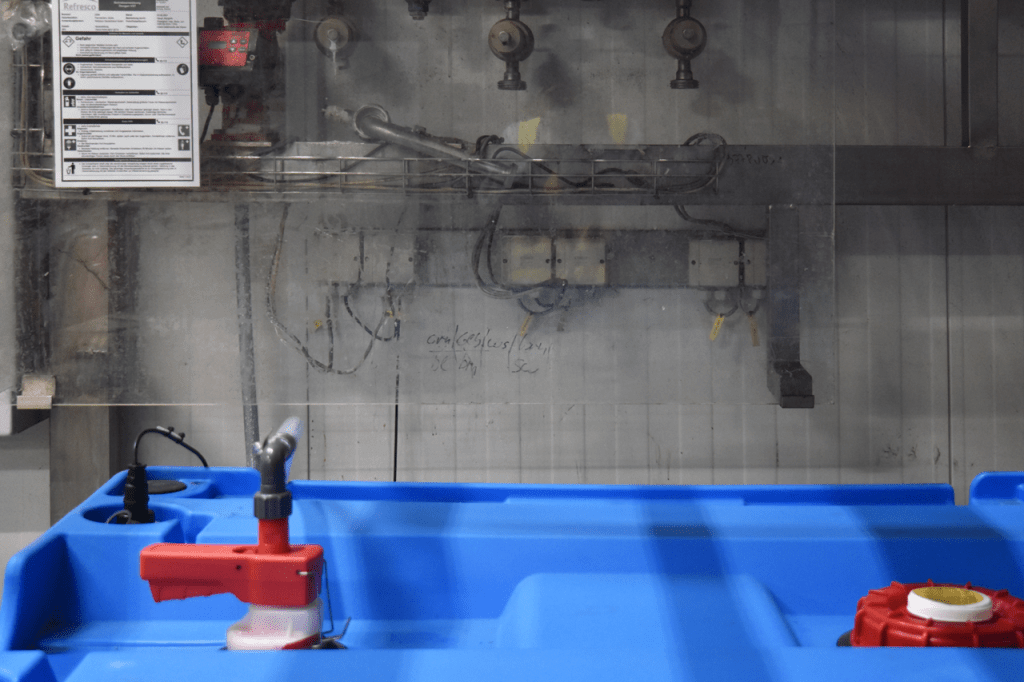

The third thing that we solved with the VARIBOX was the problem we had with a level sensor. The former sensors were connected to the suction tube to measure the level of liquid inside. This was not accurate and gave us problems. An “emergency solution” found by our employees was to use a flashlight to view and determine the level. Something we obviously don’t want.

Another safety aspect we improved was the requirement to deliver the IBC completely empty to our detergent supplier. The IBCs we had before, did not have complete emptying, which meant the IBC had to be lifted/tilted to get the last of the chemical product out. And even worse was the emergency solution to pour the remainder of the chemicals into a can, with additional risks of injuries.

What has changed since the introduction of VARIBOX for employees who work with detergents Mr. Hammel?

- Much easier working with VARIBOX Safeline: “plug-and-play”

- The cable of the empty detector does not break anymore, in the old situation this was mounted to the suction tube.

- The suction tube is no longer pulled out from the IBC, eliminating the risk of contact with chemicals.

- Previously, IBCs had to be moved with a forklift truck, now they can be moved with an electric pallet jack.

- No more open containers (we had already been informed by BGE to solve this)

Kobus Bruins: Mr. Hammel and Refresco made an excellent safety flyer!

Mr. Hammel, based on your area of expertise, what advice can you give to similar companies that use those hazardous chemical substances?

Well of course I already mentioned a lot of safety benefits. But in short: with the VARIBOX we have a cleaner and safer appearance in our factory. The handling is faster, safer, and of higher quality because we don’t have residual chemicals.

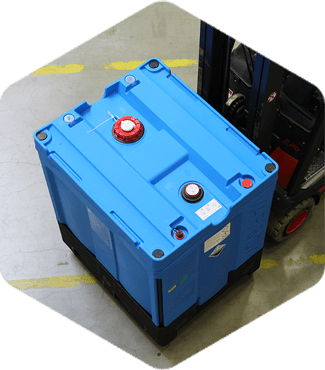

The double-walled VARIBOX FC 1000L

The double-walled VARIBOX is available in an EPDM or Viton version depending on the chemicals that will be packed in the container. This will be fully matched to the Safeline system. But of course, the VARIBOX FC is also applicable for other extractor tubes. The full containment IBCs are available in many different colors as blue, dark blue, yellow, orange, green, and natural to match your product coding. Next to that, to be 100% safe the containers are equipped with automatic venting in terms of a pressure relief vent or combi-vent.